Solid Waste

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

Gasification

Gasification is a process that converts organic- or fossil fuel-based carbonaceous materials into carbon monoxide, hydrogen and carbon dioxide. This is achieved by reacting the material at high temperatures (>700 °C), without combustion, with a controlled amount of oxygen and/or steam. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel. The power derived from gasification and combustion of the resultant gas is considered to be a source of renewable energy if the gasified compounds were obtained from biomass.

Gasifier converts biomass into a gaseous form called producer gas through different chemical reactions like dehydration, pyrolysis, combustion/oxidation and reduction in the presence of red hot charcoal. The last step, the heart of gasification, ultimately converts carbonaceous compounds of biomass into carbon monoxide, hydrogen, methane and carbon dioxide. The key factor for the reaction is carbon (C), hydrogen (H), nitrogen (N), oxygen (O) and sulphur (S) content of the biomass and gasifying agents used: air, oxygen or steam. The amount of hydrogen can be increased by using steam as a gasification agent and amount of carbon monoxide can be increased by using oxygen as a gasification agent. 1 kg of biomass having calorific value in the range of 3500-4500 kcal/kg can generate around 2.5-3.0 Nm3 producer gas having calorific value of 1000-1200 kcal/Nm3.

The advantage of gasification is that using syngas (synthesis gas H2/CO) is potentially more efficient than direct combustion of the original fuel because it can be combusted at higher temperatures or even in fuel cells, so that the thermodynamic upper limit to the efficiency defined by Carnot’s rule is higher or (in case of fuel cells) not applicable. Syngas may be burned directly in gas engines, used to produce methanol and hydrogen, or converted via the Fischer–Tropsch process into synthetic fuel. Gasification can also begin with material which would otherwise have been disposed of such as biodegradable waste. In addition, the high-temperature process refines out corrosive ash elements such as chloride and potassium, allowing clean gas production from otherwise problematic fuels.

Types of Gasifiers developed by AEL

- Updraft Gasifier

- Downdraft Gasifier

- Fluidized bed Gasifier

| Process Category | Type of Application | UP Draft Gasifier | Down Draft Gasifier | Fluidized Bed Gasifier |

|---|---|---|---|---|

| Steel Rolling mill |

|

|

||

| Ceramic Industry |

|

|

||

| Steel Pipe Industry |

|

|

||

| Rice Mill |

|

|

||

| Roasting Industries |

|

|

|

|

| Mineral Industries |

|

|

||

| Drying Process |

|

|

||

| Melting Process |

|

|

| SR NO | Benefits |

|---|---|

| 1 | High Efficiency output with minimum operation cost |

| 2 | Wide range from 500 Nm³/hr to 10000 Nm³/hr with 99.98% clean gas. |

| 3 | All kind of organic solid fuel can be used for the generation of Syngas e.g. Coal , Biomass, MSW |

| 4 | Our complete and cost-effective solution are competent to replace traditional fuels like FO, CNG, LNG, Pet Cock |

| 5 | We are manufacturing Gasifier for all kind of Thermal & Power Generation |

| 6 | Free site assistance for Installation & Operation for the first 3 months |

| 7 | Complete Plant Design and developmentsare made as per IS standard following all the regulations as per GPCB. |

Based on Application:

- Temperature requirement

- 1000-1300oC: Updraft gasifier

- 200-900oC: Fluidized bed gasifier, Downdraft gasifier

Based on fuel availability:

- Solid fuel like woods, coal:Updraft gasifier, Downdraft gasifier

- Loose biomass like sawdust, rice husk: Fluidized bed gasifier

Based on Volume Of Producer Gas Requirement:

- 500 Nm³/hr to 10000 Nm³/hr - Up Draft Gasifier

- 100 Nm³/hr to 3000 Nm³/hr - Down Draft Gasifier

- 100 Nm³/hr to 2000 Nm³/hr - Fluidized Bed Gasifier

Updraft Gasifier

Updraft gasifier designed and developed by AEL in the range of 300 Nm3/h to 10000 Nm3/h. Producer gas calorific value is high @1200 kcal/Nm3 compared to other biomass gasifier. The energy content of the gas is sufficient to use in furnace of metal melting, glass melting, cement industries, ceramic industries, mineral industries, etc where process temperature requirement is very high i.e. in the range of 1000-1300oC. Thermal efficiency of the gasifier is 60-70%. AEL has designed updraft gasifier to use the moisture and tar free gas with 99.9% pure gas. Imported coal, wood blocks or biomass briquettes are used as a fuel in the gasifier. Raw producer gas contains higher tar content which is advantage for higher calorific value of the gas but needs more cleaning equipment’s for clean gas use. A cooling cleaning train containing of cyclone separator, electro static precipitator and couple of condensers are used. This type of gasifier can be used for large capacities of up to fuel consumption of 5 t/h. Major use of this gasifiers is in ceramic and mineral industries where temperature requirement is 1100-1400oC.

Advantages of Updraft Gasifier

Advantages of Updraft Gasifier

- Updraft gasifier can be used in high temperature applications

- Higher efficiency than combustion-based systems with comparatively lower emissions level.

- Higher heat and mass transfer compared to conventional gasifiers.

- Multi-fuel flexibility followed by different combined cycle equipment for thermal & power applications.

| SR NO | MODEL NO | CAPACITY (Nm3/hr) | NET CV (1150kcal/Nm3) | COAL CONS. (kg/hr) | SHELL DIA (mm) |

|---|---|---|---|---|---|

| 1 | ENVI-U-500 | 500 | 575000 | 160-170 | 1000 |

| 2 | ENVI-U-800 | 800 | 920000 | 260-270 | 1200 |

| 3 | ENVI-U-1200 | 1200 | 1380000 | 400-420 | 1800 |

| 4 | ENVI-U-1500 | 1500 | 1725000 | 500-525 | 2000 |

| 5 | ENVI-U-2000 | 2000 | 2300000 | 650-670 | 2200 |

| 6 | ENVI-U-2200 | 2200 | 2530000 | 700-735 | 2400 |

| 7 | ENVI-U-3000 | 3000 | 3450000 | 980-1020 | 2800 |

| 8 | ENVI-U-4000 | 4000 | 4600000 | 1320-1350 | 3200 |

| 9 | ENVI-U-5000 | 5000 | 5750000 | 1650-1670 | 3400 |

| 10 | ENVI-U-6000 | 6000 | 6900000 | 1980-2000 | 3600 |

| 11 | ENVI-U-8000 | 8000 | 9200000 | 2650-2700 | 3800 |

| 12 | ENVI-U-10000 | 10000 | 115000000 | 3350-3500 | 4200 |

Downdraft Gasifier

Biomass gasification consists in the decomposition of a solid, for example, wood, by a reactive gas, for example, air, to obtain a gaseous fuel. During this process, biomass is subjected to four successive thermochemical phenomena: drying, pyrolysis, oxidation, and reduction.

- Drying: The fuel moisture is removed by evaporation. This is an endothermic process, it occurs at a temperature between 100 °C and 160 °C.

- Pyrolysis: As the temperature of the solid increases, gases are generated by dry biomass from 250 °C. These gases are constituted of non-condensable species (methane, hydrogen, carbon monoxide, carbon dioxide) and condensable vapours (tar). The solid residue from this operation is called coke and contains carbon and mineral materials.

- Oxidation: Oxidation occurs in the presence of a reactive gas (air, steam, pure oxygen, hydrogen) which condition the calorific value of the gas leaving the gasifier. The use of air as a reactive gas is more common. Oxidation is the phase that provides heat for the three phases of the gasification process.

- Reduction: The coke reacts with water vapour and carbon dioxide, thereby forming hydrogen and carbon monoxide, principal constituents of the combustible gas produced. The received combustible gases are used for power generation after passing through cleaning cooling cycle or used for the thermal application.

- Non-homogeneous biomass waste converted to a homogenous fuel gas with a considerably higher level of purity and wide applicability.

- Higher efficiency than combustion-based systems with comparatively lower emissions level.

- Multi-fuel flexibility followed by different combined cycle equipment for thermal & power applications.

- Integrated gasification combined cycles can be arranged for producing electricity, ammonia, oil, methane and hydrogen for fuel cell.

| Capital cost | INR 1.36 lakhs /kW (upto 100 kWecapacity) |

| Power | Biomass consumption 1.0 – 1.4 kg/kWh |

| Operating cost | Total operational cost - INR 5.0-7.0/kWh |

| Maintenance cost | INR 1.7 – 2.0/kWh (upto 100 kW capacity ) |

Fluidized Bed Gasifier

Fluidized bed gasifier has a special advantage over other gasifiers. The fuel is fluidized in oxygen and steam or air. Inert materials (sand or catalyst) are used as a bed material which are used for fluidization of powdery fuel and transfer of heat to it. Small particles give a better conversion because the surface area for transfer the heat is more. Since pre-process steps such as pelleting/briquetting the fuel aren’t being prerequisite, the overall operating cost is lower than other technologies. Reaction time is low compared to fixed bed gasifiers. The ash is removed dry. The temperatures are relatively low in fluidized bed gasifier, so start-up fuel requirements are lower; low-grade coals/fuels with high ash content are particularly suitable. Fuel throughput is higher than for the fixed bed gasifiers. Recycling or subsequent combustion of solids can be used to increase thermal energy recovery. Fluidized bed gasifiers are most useful for fuels that form highly corrosive ash that would damage the walls of slagging gasifiers. Biomass fuels and industrial sludge generally contain high levels of corrosive ash.

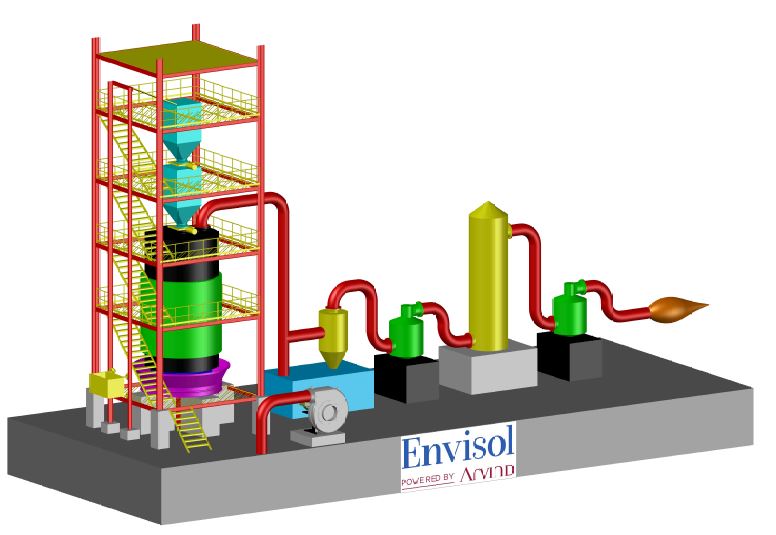

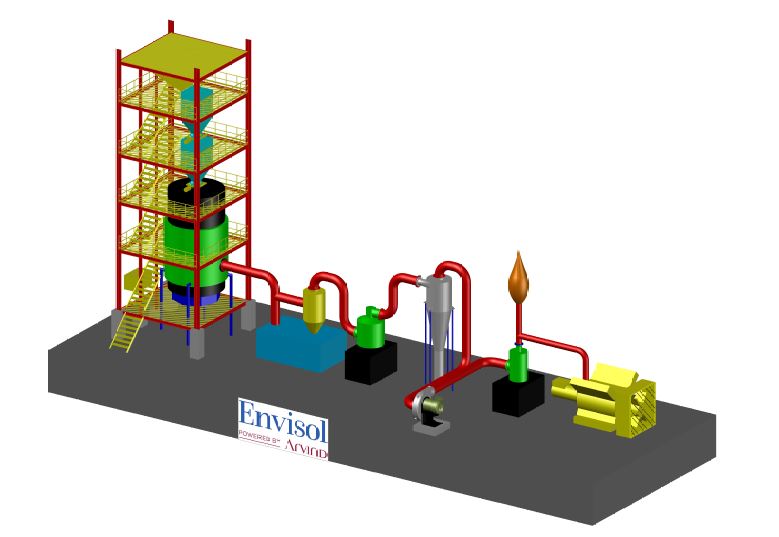

Design and developmentArvind Envisol has developed fluidized bed gasifier system particularly for thermal application meeting heat requirement in the range of 4,00,000-5,00,000 kcal/h. Our Gasification Plant consists of following components:

- Screw feeder for fuel feeding

- Fluidized bedreactor

- Distributorplate

- Coarse and fine cycloneseparators

- Organicand fabricfilters

- Regenerative blower

- Burner

- Fluidized bed gasifier has higher carbon conversion and thermalefficiency.

- Higher efficiency than combustion-based systems with comparatively lower emissionslevel.

- Higher heat and mass transfer compared to conventionalgasifiers.

- Multi-fuel flexibility followed by different combined cycle equipment for thermal &powerapplications.

- Non-homogeneous biomass waste can be converted to a homogenous fuel gas with a considerably higher level of purity and wide applicability.

- Integrated gasification combined cycles can be arranged for producing electricity, ammonia, oil, methane and hydrogen.

| SR NO | MODEL NO | CAPACITY (Nm3/hr) | NET CV (1150kcal/Nm3) | Biomass Cons. (kg/h) | Application | Pick Temp. (oC) | Power Generation (kWe) |

|---|---|---|---|---|---|---|---|

| 1 | ENVI-F-300 | 300 | 3,15,000 | 100 | Thermal,power | 1000-1100 | 65 |

| 2 | ENVI-F-500 | 500 | 5,25,000 | 165 | Thermal, power | 1000-1100 | 110 |

| 3 | ENVI-F-750 | 750 | 7,88,000 | 250 | Thermal, power | 1000-1100 | 165 |

| 4 | ENVI-F-1000 | 1000 | 10,50,000 | 335 | Thermal,power | 1000-1100 | 225 |

| 5 | ENVI-F-1200 | 1200 | 12,50,000 | 400 | Thermal,power | 1000-1100 | 265 |

| 6 | ENVI-F-1500 | 1500 | 15,75,000 | 500 | Thermal,power | 1000-1100 | 335 |

| 7 | ENVI-F-1750 | 1750 | 18,35,000 | 580 | Thermal,power | 1000-1100 | 385 |

| 8 | ENVI-F-2000 | 2000 | 21,00,000 | 665 | Thermal,power | 1000-1100 | 440 |

| 9 | ENVI-F-2200 | 2200 | 23,00,000 | 730 | Thermal,power | 1000-1100 | 490 |