Technologies

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

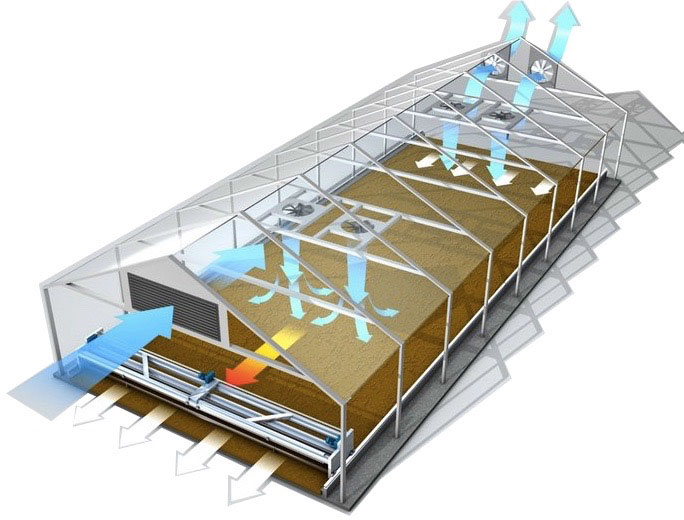

DRYING TECHNOLOGIES – SOLAR DRYER

This technology relies on the radiant energy from sun.

It can be used for drying sludge, agriculture waste, dyes and chemicals which are not radiation sensitive

Dewatered solids are distributed into the greenhouse uniformly by an automated homogeniser or manual means.

The sun’s energy passes through the greenhouse structure to heat and evaporate the moisture content in the sludge.

The enclosure protects the sludge from adverse weather while simultaneously facilitating semi-controlled environment to accelerate evaporation and encloses the odour.

The traveling bridge mixer incrementally distributes and moves the sludge along the length of the solar dryer, ensuring a properly mixed and uniformly dried product.

With full automation capability, operator time within the drying structure can be virtually eliminated.

Advanced low-temperature drying and dehumidification technology is adopted without adding chemicals and physical treatment throughout the process.

No exhaust gas or dust is discharged. With advanced automatic control technology and centralized monitoring of equipment, the moisture content of sludge after drying can be set and adjusted.

The drying process has no loss of organic components, no need to add other ingredients, and get high calorific value of dry materials, which is suitable for later resource utilization.

- Key attributes of this technology are:

Low energy demand – Natural process

Concept perfectly suites as a complimentary solution in areas with high seasonal fluctuations

High foot print

Flexibility to use alternate heat source such as waste heat for drying

Lowest operating cost

Sufficient buffer needed

Arvind Envisol provides following services for solar dryers:

Documentation and Basic Engineering Package (BEP) for civil, mechanical, & electrical works, along with instrumentation & automation

Work Processing sheets

Construction plans

Detail plans of concrete interface plant construction

Detail plans of the drying plant’s structural work and technics

Settlement of Project : For the machinery equipment and EMSR/E, I&C equipment incl. planning, construction and documentation for the compiling of the delivery plant elements, incl. interface clarification for performance on site

Initial operation for the drying plant : Stretch out over max 5 working days by procedural and electro technical educated staff, adjustment of the SPC/ PLC control system, on- the- job training of the operational staff

Compile cable plan and cable lists

Design cabinet construction

EPC and plant engineering

Staff education / training