Technologies

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

- Waste Water Primary Treatment

- Secondary/Biological Treatment

- Tertiary Treatment

- Evaporators

- Sludge Management Technologies

- Drying Technologies

DRYING TECHNOLOGIES

Technology selection is based on heat source availability, quantum of drying and type of material in scope. All drying technologies bring considerable reduction in operating cost. Modular structure and simple design makes it easier for maintenance, highly safe due to low temperature operations and no tail or harmful gases are produced during drying process

All technologies are designed to operate in all weather conditions with full automation, hence minimal manual intervention is required on periodic basis.

Correct drying technology for varied applications

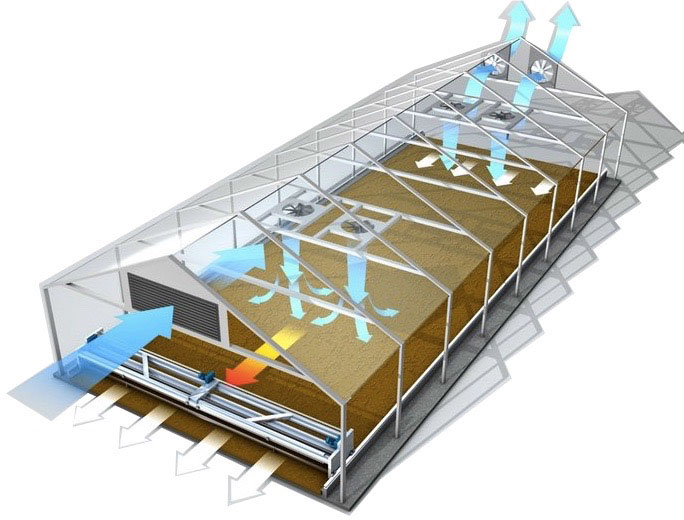

Solar Dryer:

Used for large evaporation capacities

Make use of solar radiations for material drying

Lowest in operating expenditure with continuous automated operation

Used for large evaporation capacities

Make use of solar radiations for material drying

Lowest in operating expenditure with continuous automated operation

Heat pump dryer:

Used for small and medium evaporation capacities

It is low heat dryer which uses hot air at 70 – 75?C for drying

Heat pump is used to generate hot air

Waste heat dryer:

Used for small and medium evaporation capacities

It is a low heat dryer which works on same principle as heat pump dryer but uses waste heat available in the system for drying

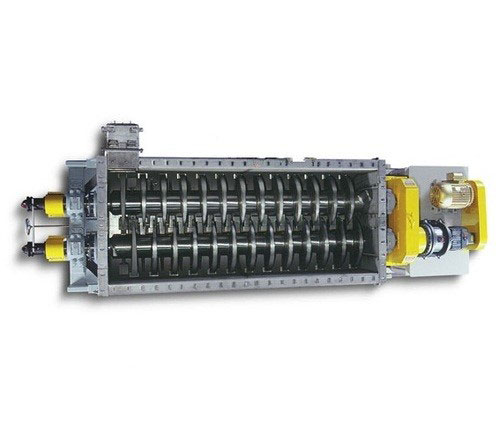

Paddle dryer:

Used for small to large evaporation capacities

It is a high heat dryer utilized steam or thermic fluid for indirectly transferring heat to the product

It can operate upto 350 ?C temperature