Technologies

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

DRYING TECHNOLOGIES – HEAT PUMP DRYER

Thermal drying technique is divided into two methods based on temperature: low-temperature drying (under 100?) and high-temperature drying (over 120?). We adopt direct low-temperature drying for the aforementioned proposal. Direct low-temperature drying makes such an effect on sludge that it produces high thermal efficiency. Moreover, low temperature protects organisms in the sludge from splitting and volatilization, while the circulation of hot air takes only water out from the sludge. The machine in scope is having a drying temperature between 45-50? (temperature of incoming dehumidification stream), while the blowing-in temperature is between 60-75? (bottom layer).

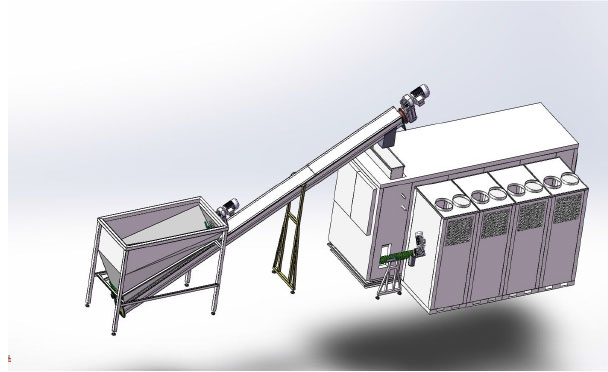

The project adopts belt type closed cabinet dehumidification heat pump drying. There is no need for additional energy (steam, thermal-conduction oil, and hot-blast air), as well as no need for treatment of the system for tail gas. The dryer in scope makes dehumidification of sludge through hot-air recycling, condensing, dehumidifying, and drying. The evaporation of the sludge moisture produces latent heat and the same can be used for the condensation of vapor.

Both processes of latent heat are equal according to the law of conservation of energy. As a result, the drying process does not require additional heat capacity. The energy consumed during the process is the electricity for the input to the compressor, fan, and motor.

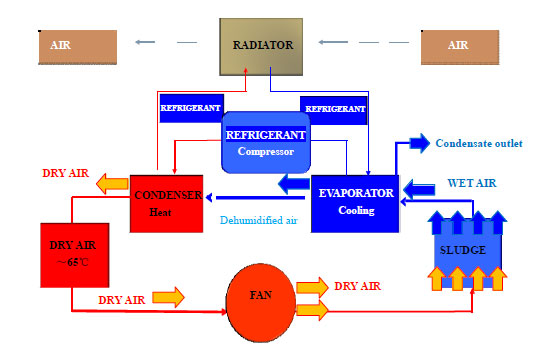

Dehumidification heat pump is equipment that utilizes a refrigeration system to cool and dehumidify hot and wet air. Through the principle of heat pump, it recycles the latent heat released from steam congealing to water liquid. Dehumidification heat pump = Dehumidification (moist dehumidifying) + heat pump (energy recycling). Dehumidification heat pump can collect all the latent heat and sensible heat during air exhaust, bringing no waste heat to the outside. Please find below the principle diagram of drying.

Wet sludge is shaped to a certain size by slitter and then enters low-temperature drying equipment. Sludge distributor is installed in the equipment to distribute sludge evenly on the conveyor track. While sludge moving on the conveyor, moisture is carried away by the flowing air provided by the circulating fan, and eventually, the dry sludge is discharged. After the water in the sludge is taken away by air, it will get discharged into the condenser.

Air after condensation and dehydration is heated by heater/compressor and then enter into sludge dryer, which is recycled. Refrigerant is compressed by the compressor and after expansion heat is released and excess heat is eliminated by radiator and refrigerant is returned to the condenser. There are many groups of temperature, pressure, humidity, and sensors in the low-temperature drying equipment of sludge, which can monitor and automatically regulate the operation of the device to ensure the dryness of the sludge.

Advanced low-temperature drying and dehumidification technology is adopted without adding chemicals and physical treatment throughout the process. No exhaust gas or dust is discharged. With advanced automatic control technology and centralized monitoring of equipment, the moisture content of sludge after drying can be set and adjusted. The drying process has no loss of organic components, no need to add other ingredients, and get the high calorific value of dry materials, which is suitable for later resource utilization.