Solid Waste

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

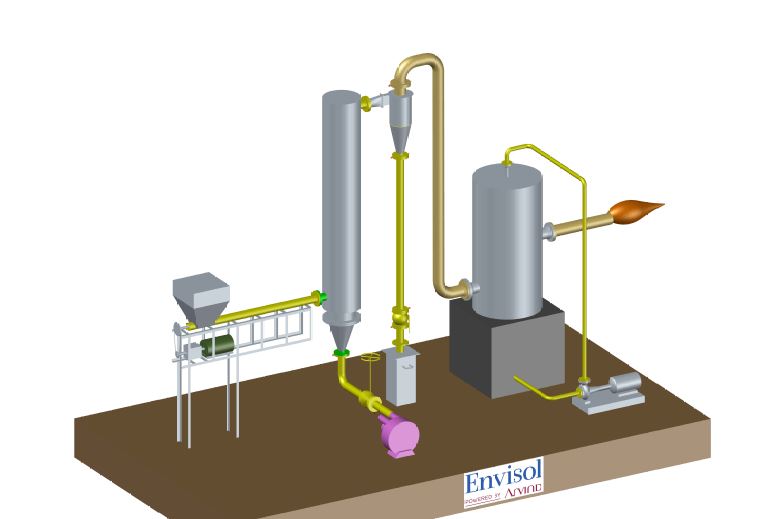

Fluidized Bed Gasifier

Fluidized bed gasifier has a special advantage over other gasifiers. The fuel is fluidized in oxygen and steam or air. Inert materials (sand or catalyst) are used as a bed material which are used for fluidization of powdery fuel and transfer of heat to it. Small particles give a better conversion because the surface area for transfer the heat is more. Since pre-process steps such as pelleting/briquetting the fuel aren’t being prerequisite, the overall operating cost is lower than other technologies. Reaction time is low compared to fixed bed gasifiers. The ash is removed dry. The temperatures are relatively low in fluidized bed gasifier, so start-up fuel requirements are lower; low-grade coals/fuels with high ash content are particularly suitable. Fuel throughput is higher than for the fixed bed gasifiers. Recycling or subsequent combustion of solids can be used to increase thermal energy recovery. Fluidized bed gasifiers are most useful for fuels that form highly corrosive ash that would damage the walls of slagging gasifiers. Biomass fuels and industrial sludge generally contain high levels of corrosive ash.

Design and development

Design and development

Arvind Envisol has developed fluidized bed gasifier system particularly for thermal application meeting heat requirement in the range of 4,00,000-5,00,000 kcal/h. Our Gasification Plant consists of following components:

- Screw feeder for fuel feeding

- Fluidized bedreactor

- Distributorplate

- Coarse and fine cycloneseparators

- Organicand fabricfilters

- Regenerative blower

- Burner

- Fluidized bed gasifier has higher carbon conversion and thermalefficiency.

- Higher efficiency than combustion-based systems with comparatively lower emissionslevel.

- Higher heat and mass transfer compared to conventionalgasifiers.

- Multi-fuel flexibility followed by different combined cycle equipment for thermal &powerapplications.

- Non-homogeneous biomass waste can be converted to a homogenous fuel gas with a considerably higher level of purity and wide applicability.

- Integrated gasification combined cycles can be arranged for producing electricity, ammonia, oil, methane and hydrogen.

| SR NO | MODEL NO | CAPACITY (Nm3/hr) | NET CV (1150kcal/Nm3) | Biomass Cons. (kg/h) | Application | Pick Temp. (oC) | Power Generation (kWe) |

|---|---|---|---|---|---|---|---|

| 1 | ENVI-F-300 | 300 | 3,15,000 | 100 | Thermal,power | 1000-1100 | 65 |

| 2 | ENVI-F-500 | 500 | 5,25,000 | 165 | Thermal, power | 1000-1100 | 110 |

| 3 | ENVI-F-750 | 750 | 7,88,000 | 250 | Thermal, power | 1000-1100 | 165 |

| 4 | ENVI-F-1000 | 1000 | 10,50,000 | 335 | Thermal,power | 1000-1100 | 225 |

| 5 | ENVI-F-1200 | 1200 | 12,50,000 | 400 | Thermal,power | 1000-1100 | 265 |

| 6 | ENVI-F-1500 | 1500 | 15,75,000 | 500 | Thermal,power | 1000-1100 | 335 |

| 7 | ENVI-F-1750 | 1750 | 18,35,000 | 580 | Thermal,power | 1000-1100 | 385 |

| 8 | ENVI-F-2000 | 2000 | 21,00,000 | 665 | Thermal,power | 1000-1100 | 440 |

| 9 | ENVI-F-2200 | 2200 | 23,00,000 | 730 | Thermal,power | 1000-1100 | 490 |