Solid Waste

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

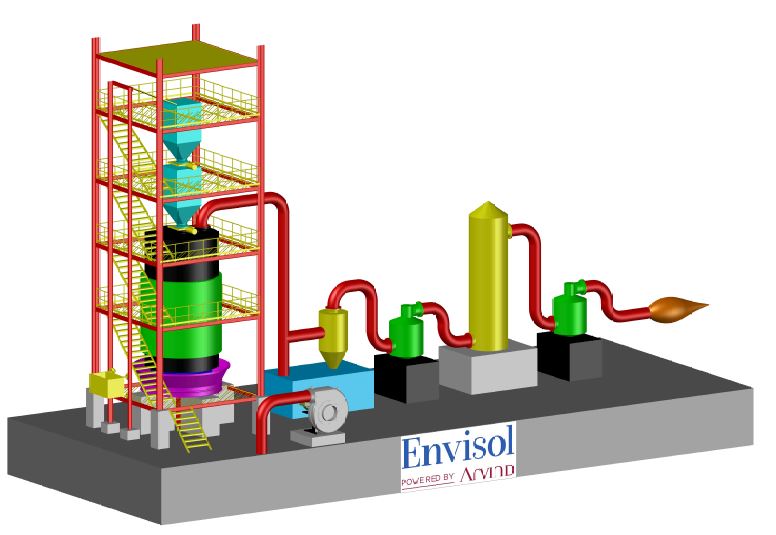

Updraft Gasifier

Updraft gasifier designed and developed by AEL in the range of 300 Nm3/h to 10000 Nm3/h. Producer gas calorific value is high @1200 kcal/Nm3 compared to other biomass gasifier. The energy content of the gas is sufficient to use in furnace of metal melting, glass melting, cement industries, ceramic industries, mineral industries, etc where process temperature requirement is very high i.e. in the range of 1000-1300oC. Thermal efficiency of the gasifier is 60-70%. AEL has designed updraft gasifier to use the moisture and tar free gas with 99.9% pure gas. Imported coal, wood blocks or biomass briquettes are used as a fuel in the gasifier. Raw producer gas contains higher tar content which is advantage for higher calorific value of the gas but needs more cleaning equipment’s for clean gas use. A cooling cleaning train containing of cyclone separator, electro static precipitator and couple of condensers are used. This type of gasifier can be used for large capacities of up to fuel consumption of 5 t/h. Major use of this gasifiers is in ceramic and mineral industries where temperature requirement is 1100-1400oC.

Advantages of Updraft Gasifier

Advantages of Updraft Gasifier

- Updraft gasifier can be used in high temperature applications

- Higher efficiency than combustion-based systems with comparatively lower emissions level.

- Higher heat and mass transfer compared to conventional gasifiers.

- Multi-fuel flexibility followed by different combined cycle equipment for thermal & power applications.

| SR NO | MODEL NO | CAPACITY (Nm3/hr) | NET CV (1150kcal/Nm3) | COAL CONS. (kg/hr) | SHELL DIA (mm) |

|---|---|---|---|---|---|

| 1 | ENVI-U-500 | 500 | 575000 | 160-170 | 1000 |

| 2 | ENVI-U-800 | 800 | 920000 | 260-270 | 1200 |

| 3 | ENVI-U-1200 | 1200 | 1380000 | 400-420 | 1800 |

| 4 | ENVI-U-1500 | 1500 | 1725000 | 500-525 | 2000 |

| 5 | ENVI-U-2000 | 2000 | 2300000 | 650-670 | 2200 |

| 6 | ENVI-U-2200 | 2200 | 2530000 | 700-735 | 2400 |

| 7 | ENVI-U-3000 | 3000 | 3450000 | 980-1020 | 2800 |

| 8 | ENVI-U-4000 | 4000 | 4600000 | 1320-1350 | 3200 |

| 9 | ENVI-U-5000 | 5000 | 5750000 | 1650-1670 | 3400 |

| 10 | ENVI-U-6000 | 6000 | 6900000 | 1980-2000 | 3600 |

| 11 | ENVI-U-8000 | 8000 | 9200000 | 2650-2700 | 3800 |

| 12 | ENVI-U-10000 | 10000 | 115000000 | 3350-3500 | 4200 |