Solid Waste

Arvind Envisol has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery.

Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications.

Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We

have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

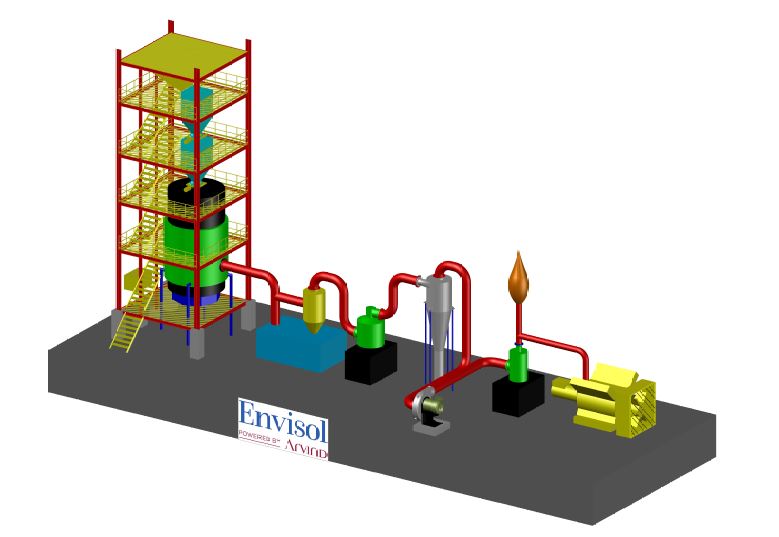

Downdraft Gasifier

Biomass gasification consists in the decomposition of a solid, for example, wood, by a reactive gas, for example, air, to obtain a gaseous fuel. During this process, biomass is subjected to four successive thermochemical phenomena: drying, pyrolysis, oxidation, and reduction.

- Drying: The fuel moisture is removed by evaporation. This is an endothermic process, it occurs at a temperature between 100 °C and 160 °C.

- Pyrolysis: As the temperature of the solid increases, gases are generated by dry biomass from 250 °C. These gases are constituted of non-condensable species (methane, hydrogen, carbon monoxide, carbon dioxide) and condensable vapours (tar). The solid residue from this operation is called coke and contains carbon and mineral materials.

- Oxidation: Oxidation occurs in the presence of a reactive gas (air, steam, pure oxygen, hydrogen) which condition the calorific value of the gas leaving the gasifier. The use of air as a reactive gas is more common. Oxidation is the phase that provides heat for the three phases of the gasification process.

- Reduction: The coke reacts with water vapour and carbon dioxide, thereby forming hydrogen and carbon monoxide, principal constituents of the combustible gas produced. The received combustible gases are used for power generation after passing through cleaning cooling cycle or used for the thermal application.

- Non-homogeneous biomass waste converted to a homogenous fuel gas with a considerably higher level of purity and wide applicability.

- Higher efficiency than combustion-based systems with comparatively lower emissions level.

- Multi-fuel flexibility followed by different combined cycle equipment for thermal & power applications.

- Integrated gasification combined cycles can be arranged for producing electricity, ammonia, oil, methane and hydrogen for fuel cell.

| Capital cost | INR 1.36 lakhs /kW (upto 100 kWecapacity) |

| Power | Biomass consumption 1.0 – 1.4 kg/kWh |

| Operating cost | Total operational cost - INR 5.0-7.0/kWh |

| Maintenance cost | INR 1.7 – 2.0/kWh (upto 100 kW capacity ) |