Solutions

Arvind Envisol is a world-class water management company providing end to end solutions for water treatment, industrial wastewater treatment,

sewage treatment, desalination and Zero Liquid Discharge (ZLD) solutions at minimal costs. We have experience in designing and treating hard to

treat effluent at a very nominal cost. Our expertise lies in bringing our teams together for the seamless implementation of the project. We work to

implicate new technologies, reduce footprint, save energy, and deliver a state of the art water treatment plant.

- Effluent Treatment Plant (ETP)

- Sewage Treatment Plant (STP)

- Packaged Sewage Treatment Plant (PSTP)

- Zero Liquid Discharge (ZLD)

- Solid Waste Treatment (SWT)

PACKAGED SEWAGE TREATMENT PLANT (PSTP)

Arvind Packaged Sewage Treatment Plant (PSTP) is housed in specially designed and highly durable FRP tank. These tanks are compact which can be utilized in a decentralized manner at any location, either it’s underground or above the ground.

The Arvind Packaged STP is designed to bring the treated sewage parameters (BOD, COD, TSS, TN etc.) below the permissible limit which is stipulated by the Pollution Control Board. MBBR technology is used in this system.

PROCESS DESCRIPTION OF ARVIND PACKAGE STP

1. Preliminary Treatment

The influent sewage water passes through a bar screen to remove all the large objects like cans, rags, sticks, plastic packets etc. which are carried in the sewage stream.

2. Secondary Treatment

a. Anaerobic Zone-

The first stage of PSTP is an oxygen-depleted anaerobic zone in which the solids in raw sewage gets settled while allowing the scum to float on the surface. It is a zone in which the settled sludge is stabilized by anaerobic digestion.

b. Anoxic Zone-

The sewage then enters the anoxic zone in which denitrification of the wastewater stream is accomplished by returning the activated sludge from the final sedimentation zone to the anoxic zone; wherein dissolved oxygen levels are maintained approximately as 0.2 to 0.5 mg/l. In the denitrification process, anoxic microbes break down to the existing nitrates, this results in the release of inert nitrogen gas into the atmosphere.

c. Aeration Zone-

The sewage from solid separation zone flows into the aeration zone. Air is diffused with the help of air blowers which encourages the growth of bacteria cultures in and around the floating plastic media added in the aeration zone. The MBBR media provides the extended surface area for the growth of microorganisms.

d. Sedimentation Zone-

The next step of treatment involves the sedimentation zone where organic waste is settled. The settled waste in the bottom of the tank is pumped back to the anoxic zone as a return sludge, which is done to ensure that the quality of effluent must pass the stipulated sewage parameters.

3. Tertiary Treatment System:

The secondary treated sewage is then passed through the Pressure Sand Filter and Activated Carbon Filter for the removal of suspended solids (TSS), colour, and odour. The treated water is then disinfected using sodium hypochlorite before it is reused.

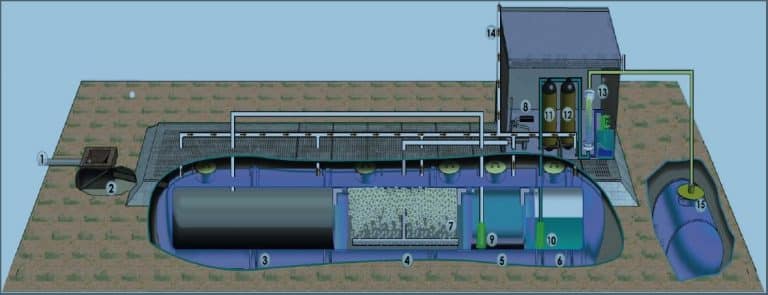

1. INFLUENT

2. BAR SCREEN CHAMBER

3. ANAEROBIC & ANOXIC ZONE

4. AEROBIC MBBR ZONE

5. FINAL SEDIMENTATION

6. FILTER FEED TANK

7. MBBR MEDIA

8. AIR BLOWERS

9. RECIRCULATION PUMP

10. FILTER FEED PUMP

11. PRESSURE SAND FILTER

12. ACTIVATED CARBON FILTER

13. DISINFECTION

14. AIR VENT

15. TREATED WATER TANK

| Key Points | Arvind MBBR FRP-PSTP | MS-EP / RCC Conventional STP |

|---|---|---|

| Performance | Decomposition of organic waste is consistent throughout the year | Seasonal variation is observed |

| Monitoring of MLSS & F/M Ratio | Required | Not Required |

| Sludge Removal | Once in 18-24 months | Once in a month |

| Chemicals & Equipment for Sludge Dewatering and Treatment | Required | Once in a month |

| Skilled Supervision | Not Required | Required |

| O & M Cost | 70% reduction compared to conventional STPs | Much higher |

| Tank Maintenance | Leak & rust proof. No root integration & fungal growth | Prone to leak & rust, root integration & fungal growth |

| Tank Maintenance and Durability | Maintenance free and much more durable | Requires frequent maintenance. Much lower durability |

| Installation Lead Time | Within 7 to 10 days | Much higher |

| Upgradation and Relocation | Possible | Not possible |

| SR. NO. | PRODUCTS | CAPACITY RANGE |

|---|---|---|

| 1 | FRP Package Sewage Treatment Plant (ENVI Model) | 2 KLD to 500 KLD |

| 2 | FRP Anaerobic Septic Tank (FAST Model) | 10 KL to 150 KL |

| 3 | FRP Waste Water Equalization / Collection Tank (FET Model) | 10 KL to 150 KL |

| 4 | FRP Water Storage Tank (FWST Model) | 10 KL to 150 KL |

| 5 | FRP Fir Fighting Water Storage Tank (FFST Model) | 10 KL to 150 KL |

APPLICATION AND USES

- Residential and Commercial Complex

- Public Garden and National Park

- Hotel & Resorts

- Restaurants

- Industries

- Institutions

- Hospitals

- Temples

- Government Offices

- Labour Quarters

- Township

- Hostels